Motion Engineering is dedicated to providing efficient fuel manifold solutions for the asphalt industry. The range of fuel manifolds we stock, integral to the functionality of asphalt plants, are designed for seamless integration and optimal performance. Motion Engineering is your supplier for a diverse range of fuel manifold solutions, each designed to enhance efficient and safe fuel delivery for various asphalt plant applications.

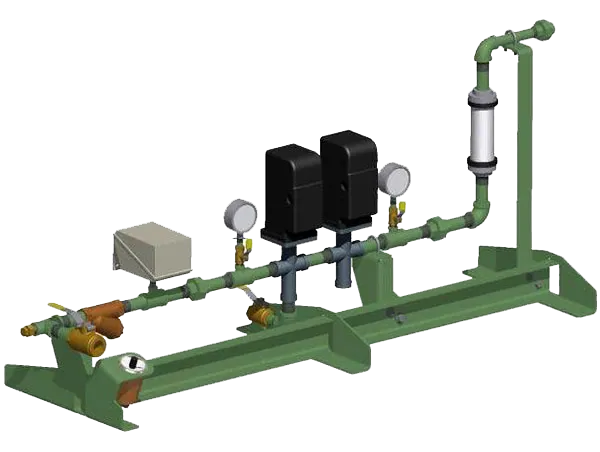

Prepiped Liquid Propane Manifold (PLPM)

Motion Engineering’s offerings include the Hauck PLPM, a groundbreaking solution in liquid propane delivery. This prepiped LP train, factory-assembled for quick and straightforward installation, is a testament to efficiency and safety in fuel management.

- Factory Assembled: Ensures quick and straightforward installation.

- Versatility: Suitable for liquid propane and various propane/butane mixtures.

- Application Range: Ideal for single burner applications in asphalt, mining, and air heating.

- Key Features:

- Mounting Rack

- Inlet Ball Valve

- “Y” Strainer

- In-line Flow Meter

- Low/High LP Pressure Switch

- Inlet Pressure Gauge & Needle Valve

- Two Automatic Safety Shutoff Valves with Visual Indication

- Outlet Pressure Gauge & Needle Valve

- Three Safety Pressure Relief Valves

- Capacity and Rating: Rated for 300 psig (2070 kPa), with capacities from approximately 400 to 2300 gph (1510 to 8700 lph).

The PLPM manifold is a reliable solution for diverse industrial needs, offering both versatility and safety in fuel delivery, ensuring your operations remain dynamic and efficient.

Prepiped Oil / Heavy Oil Manifold (POM/POM-H)

To help you enhance fuel management efficiency, Motion Engineering offers the Hauck POM and POM-H oil manifolds. These solutions, tailored for light and heavy fuel oil applications, streamline installation and maintenance processes.

- Assembly: Factory assembled for ease of installation.

- Application: Suitable for light fuel oil (POM) and heavy fuel oil (POM-H) applications.

- POM Features:

- Mounting Rack

- Inlet Ball Valve

- “Y” Strainer

- In-line Flow Meter

- Low/High Oil Pressure Switch

- Inlet Pressure Gauge & Needle Valve

- Two Automatic Safety Shutoff Valves with Visual Indication

- Outlet Pressure Gauge & Needle Valve

- Additional POM-H Features: Low/High Oil Temperature Controller, Normally Open Return Solenoid Valve, Return Line Ball Valve.

- Capacity and Rating: For fuel oil up to 250°F (121°C) and 80psig (550 kPa). Light fuel oil from 300 to 1800 gph (1140 to 6810 lph) and heavy fuel oil from 288 to 1720 gph (1090 to 6510 lph).

The POM and POM-H manifolds cater to a broad spectrum of industrial requirements, ensuring reliable and safe fuel oil delivery for various applications.

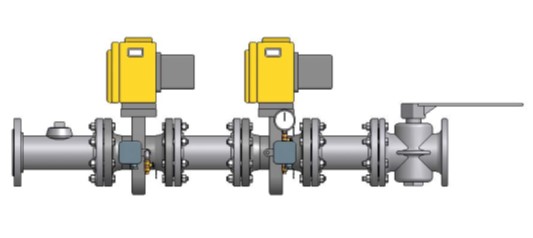

Prepiped Gas Manifold (PGM)

Improve your operation’s gas fuel delivery with the Hauck Prepiped Gas Manifold (PGM). Designed for efficiency and compliance, the PGM is an essential component in modern fuel gas supply systems.

- Ease of Installation: Factory assembled and prepiped.

- Compliance: Meets NFPA requirements, aiding in insurance approval for burner installations.

- Application: Suitable for single and multiple burner applications.

- Features:

- High and Low Gas Pressure Switches

- Valve Leakage Test Cocks for Leak Testing

- Optional Automatic Vent Valve

- Integrated Valve Tightness Control Available

- Series Variations:

- 2000 Series for Single Burner Applications

- 6000 Series for Multiple Burners

- 3000 Series for Asphalt Plant Operations

The PGM range, with its comprehensive features and adaptability, is ideal for efficient and compliant gas fueling in a variety of industrial settings.

Choose Motion Engineering for Optimal Fuel Manifold Solutions

Motion Engineering offers advanced fuel manifold solutions that stand out in the asphalt industry. Our commitment to innovation and safety is evident in the range of PLPM, POM/POM-H, and PGM manifolds we supply, which are designed to meet the diverse needs of asphalt plant operations. For detailed information or to discuss specific requirements, we encourage you to contact us. Let Motion Engineering be your go-to source for fuel manifold solutions that elevate your operations.