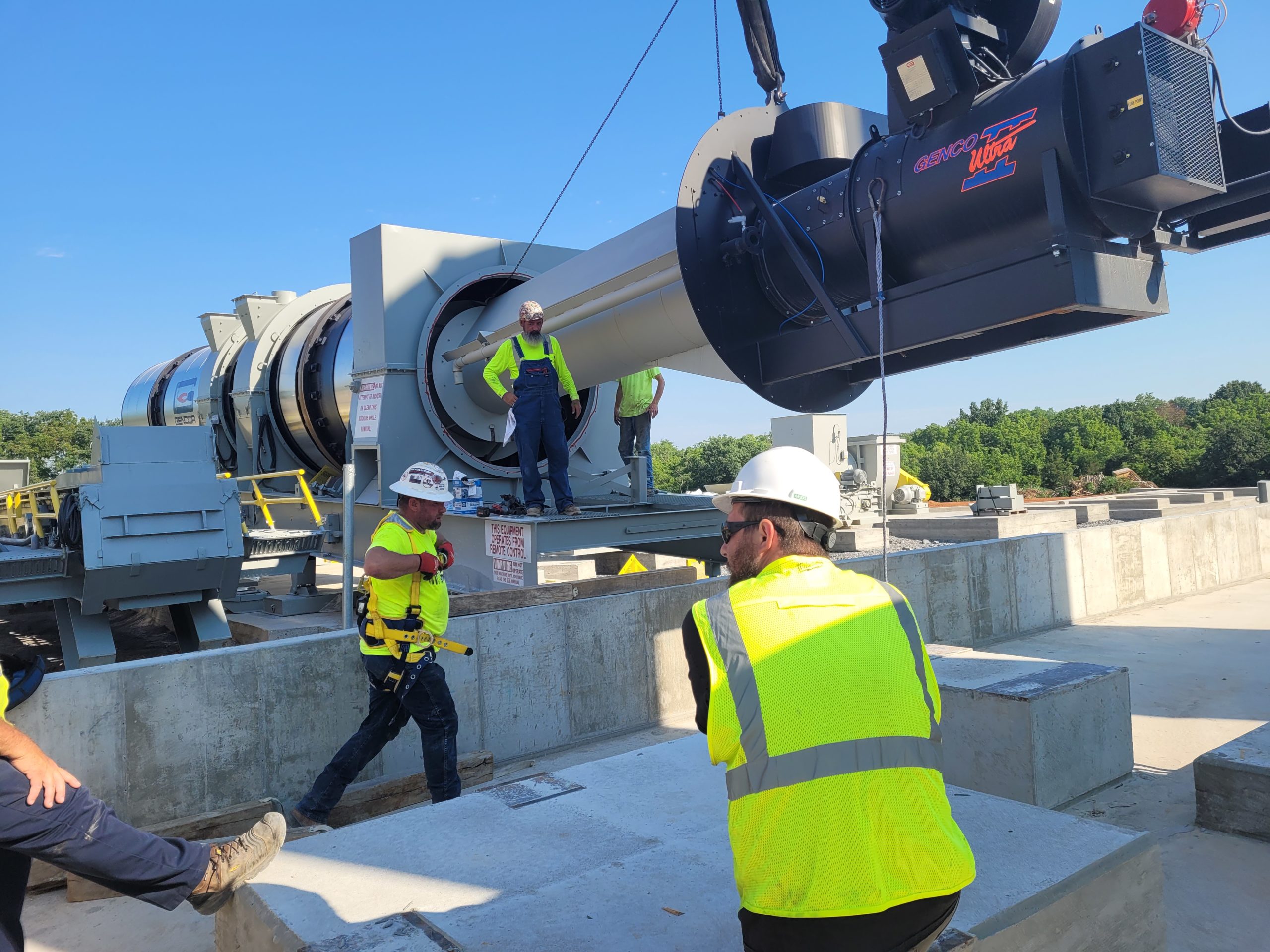

At Motion Engineering, we specialize in asphalt plant construction and offer comprehensive services to meet all your installation and setup needs. With extensive experience working with several original equipment manufacturers (OEMs), including Gencor, Almix, and Astec, we have the expertise to handle projects of any scale. Whether you require assistance with field fabrication or custom integration, or you have questions regarding the functionality and setup of new or used equipment, our team is here to provide reliable solutions.

Experienced with Major Manufacturers

We have a successful track record of erecting asphalt plants from renowned manufacturers such as Gencor, Almix, and Astec. Our team’s familiarity with their equipment ensures a seamless installation process and guarantees optimal performance. When it comes to asphalt plant set up, we have the expertise and asphalt plant knowledge to deliver outstanding results.

Customized Solutions for Plant Setup

At Motion Engineering, we understand that every project is unique. That’s why we offer customized services tailored to your specific needs. Whether you require a full turnkey solution or prefer assistance with specific aspects of plant setup, we can accommodate your requirements. Motion Engineering will work closely with you to develop a plan that suits your timeline, budget, and objectives. We ensure that your asphalt plant is installed efficiently and operates at its full potential.

Sell Your Old Asphalt Plant

If you’re considering a new asphalt plant, we can help offset the cost by purchasing your old plant and equipment. With our specialization in preowned equipment, we have the workforce and expertise to recondition your old equipment, maximizing its value. Additionally, as we buy asphalt plants and equipment, we often have complete ones available for sale. So, if you’re searching for a new plant or need to sell your existing one, Motion Engineering is your trusted partner.

Partner with Motion Engineering for Asphalt Plant Construction

When it comes to asphalt plant construction, Motion Engineering is here for you! Our team is dedicated to providing top-notch services and ensuring your project’s success. From installation and setup to equipment purchase and sale, we handle it all. Contact us today for a quote on setting up a new asphalt plant or to discuss your specific needs. We want to help improve the efficiency of your asphalt production!