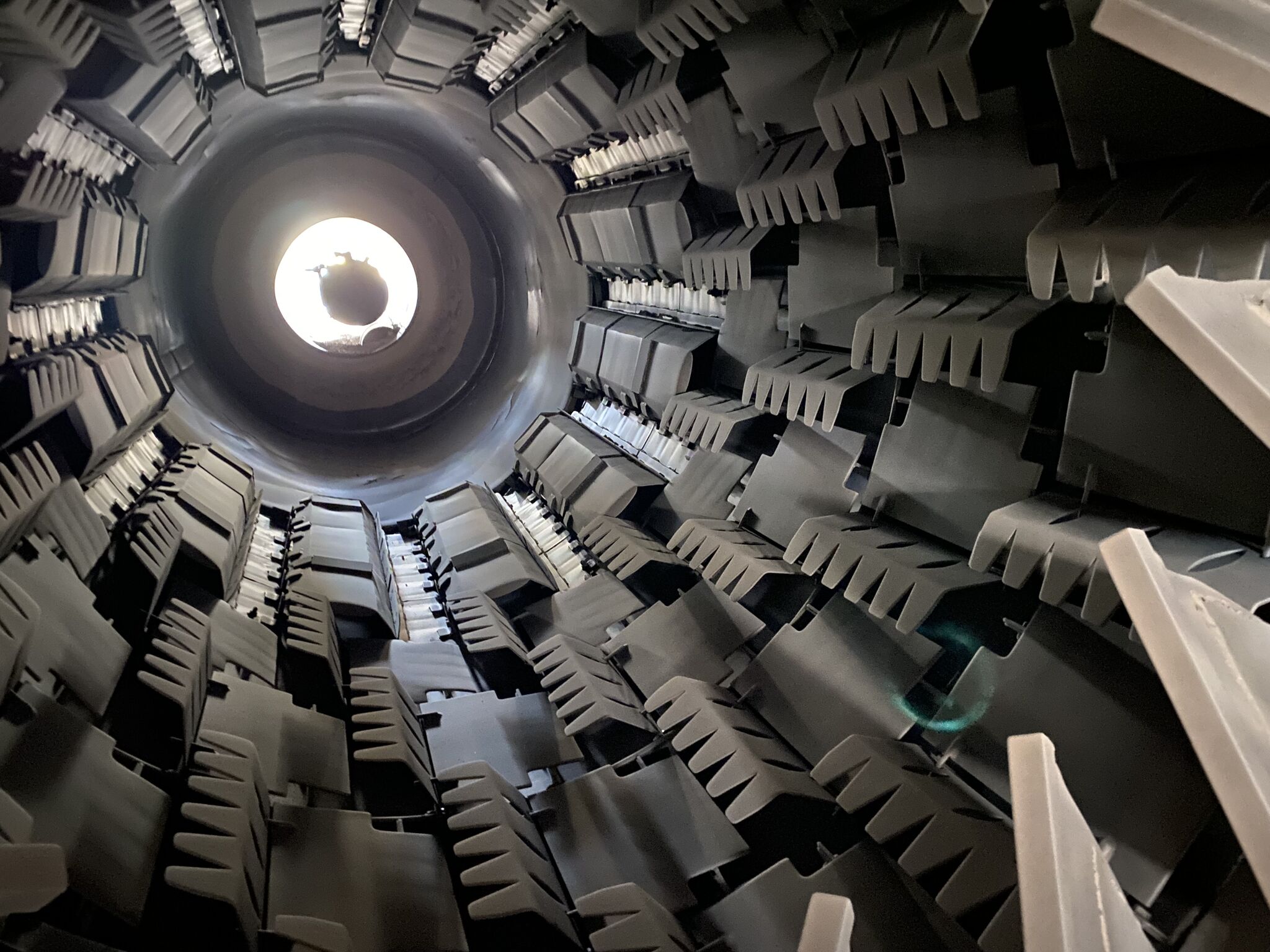

Drum liners are specialized protective barriers designed to line the interior of your drum. These liners act as a shield between the drum shell and the materials being mixed within. Liners are particularly beneficial due to the highly abrasive materials that can cause wear and damage. An additional layer of protection can preserve the drum shell’s integrity, ensuring its longevity and avoiding the need for costly shell replacements. These liners are typically made from durable materials such as abrasion-resistant steel, offering excellent wear resistance and extending the life of the drum.

Motion Engineering has the liners you need to preserve the integrity and longevity of your drums. Our industrial aggregate specialists can come out to your site to accurately measure your drum to ensure the proper fit so that you can protect your investment, ensure the longevity of your drums, and minimize downtime.

Benefits of Drum Liners

As you might expect, there are numerous benefits to using drum liners. The most significant of these benefits is their ability to protect the integrity of the drum shell and reduce the need for costly maintenance services.

Protecting the Integrity of the Drum Shell

Drum liners are an essential solution for protecting the exterior shell of your drum. They act as a barrier between the abrasive materials being processed within the drum and the drum shell itself. By preventing direct contact between the materials and the shell, drum liners help to avoid the need for shell replacement and ensure the longevity of the drum. This added layer of protection is particularly beneficial in locations where highly abrasive materials are being run through the drum, minimizing wear and extending the lifespan of the drum.

Reducing the Need for Costly Maintenance Services

Installing these types of liners can also significantly reduce the need for costly maintenance services. Using high-quality abrasion-resistant steel materials prevents premature wear on the drum. This proactive approach to drum maintenance acts as a form of preventative maintenance, reducing the likelihood of costly repairs or drum replacements. With our drum liner solutions, you can minimize downtime, improve operational efficiency, and save on maintenance expenses.

Key Features of Drum Liners

The benefits of drum liners are made possible by a few key features of their construction. These features, coupled with the high-quality materials used to construct them, make these liners flexible and durable enough to provide outstanding protection for your aggregate drums.

Custom Fit Liners

At Motion Engineering, we know selecting the right material is crucial to protect your equipment. The abrasion-resistant steel liners we install are designed to be welded in sections within the drum, providing a seamless protective layer.

High-Quality Materials

We prioritize the use of high-quality abrasion-resistant steel materials for our drum liners. This choice of material provides excellent durability and wear resistance, ensuring that these liners can withstand the most abrasive materials and demanding operating conditions. By utilizing top-grade steel, we offer added strength and wear life to your drums, enhancing their longevity and minimizing the risk of damage.

Why Choose Motion Engineering for Drum Liner Solutions

Motion Engineering sells reliable and robust liners for your aggregate drums. With our expertise in drum protection and maintenance, we are able to provide our customers with the highest quality liners on the market. When you choose Motion Engineering, you can trust that your drums are in safe hands. Additionally, we are available for all of your asphalt plant consultation needs!