Motion Engineering provides all of our aggregate-producing partners with comprehensive solutions for all their asphalt plant equipment needs, including complete asphalt plants for sale. As a second-generation family-owned business, we have been serving the industry for over three decades and have earned a reputation for providing innovative and efficient aggregate manufacturing solutions.

Our Complete Asphalt Plant Equipment

We offer a wide range of complete asphalt plant equipment designed to meet the specific needs of our customers. The equipment we distribute is of the highest quality, built to last, and capable of withstanding even the toughest of working conditions. We also offer customized solutions to meet the unique requirements of our clients.

The asphalt mixing plant equipment we offer includes, but is not limited to:

- Burners: The burner lines we sell are of the highest quality, efficient, and environmentally friendly. They are capable of burning a variety of fuels, including natural gas, propane, diesel, and heavy oils.

- Baghouses: These baghouses are designed to meet the latest environmental regulations and are capable of handling high volumes of dust and pollutants. We offer a range of baghouses to suit the needs of any asphalt plant.

- Control Systems: These advanced control systems are designed to optimize the performance of your asphalt plant, reduce downtime, and increase productivity. We offer a range of control systems to suit the needs of any asphalt plant.

- Silos & Silo Systems: We offer a wide range of high-quality silo storage solutions ranging from 100-300 Ton Capacities for all of your hot-mix storage needs. Check out our inventory of used silo systems for sale!

- Liquid AC Storage Tanks: Our offerings in this category include essential emulsion, water, and calibration tanks for both new and existing tank farms.

- Drum Mixers: These drum mixers are of the highest quality, built to last, and are capable of producing high-quality asphalt mixes. We offer both parallel flow and counterflow drum mixers to suit the needs of any asphalt plant.

- Cold Feed Systems: The cold feed systems we distribute are designed to accurately and reliably feed aggregates into your asphalt plant. We offer a range of cold feed systems to suit the needs of any asphalt plant.

Used Asphalt Plant Equipment

In addition to the variety of plant equipment we provide, we offer both new and used options to choose from. Used is an excellent way to go when it comes to equipment for aggregate plants. We understand how expensive it can be to purchase and upkeep your essential pieces of equipment. Additionally, new items like burners and storage tanks can cost a pretty penny. With that in mind, we prioritize offering you attractive, used equipment options.

Our Commitment to Quality and Customer Service

We at Motion Engineering provide our customers with the highest level of quality and customer service. We are available to you for routine maintenance, repairs, breakdowns, and specialty projects. We also offer consultation services to help our customers optimize the performance of their asphalt plants.

What You Need to Know About Asphalt Plant Equipment

Asphalt plant equipment is used in the production of asphalt mixes used in road construction, parking lots, and other paving applications. Asphalt plants consist of a range of equipment, including burners, baghouses, control systems, drum mixers, and cold feed systems. Each piece of equipment plays a critical role in the production of high-quality asphalt mixes.

Contact Us To Learn More

At Motion Engineering, we are committed to providing our customers with complete asphalt plant equipment solutions that are tailored to their needs. To learn how we can optimize your asphalt plant’s performance or to inquire about purchasing a complete asphalt plant, contact us today!

Complete Asphalt Plants for Sale

300 Ton Per Hour Parallel Flow Asphalt Plant

Location: Marquette, MI

- (6) Virgin Aggregate Bins 12’ X 9’

- 4 Bin System/2 Bin System Feeding 1 Shaker Screen

- (2) Recycle Bins 7’7” X 16’

- Hauck Starjet 580 Burner

- 47’ X 9’ Barber Green Drum

- 60,000 CFM Standard Havens Baghouse

- 2MM BTU Stansteel Hot Oil Heater (Gas/Oil) w/ Power Flame Burner

- Hot Oil Heater Fuel Tank

- (3) 30K Horizontal AC Storage Tanks

- (2) 200 Ton Storage Silos

- 400 Ton/Hr Drag Slat

- Vertical Used Oil Tank

- 100 Ton Capacity Truck Scale

- Tool Trailer/Workshop

- Systems Blending Controls

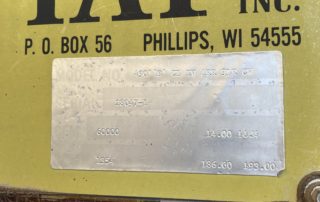

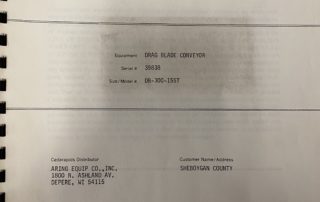

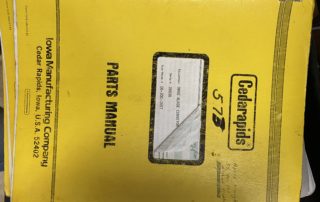

250-300 Ton Per Hour Cedar Rapids Parallel Flow Continuous Mix Plant

Location: Sheboygan, WI

- 7’ x 35’ Parallel Flow Drum

- 75 MM BTU ESII Burner LP

- 300 Ton Per Hour Drag Slat

- 120 Ton Silo Storage

- 60,000 CFM Dillman Baghouse (reverse air)

- Updated Single Bin Recycle System (CWMF) 9’ x 14’ bin

- (4) 10’ x 14’ Cold Feed Bin System

- 30,000 Horizontal AC Storage Tank-CEI

- CEI 1MM BTU Gas/Oil Burner

- Control House 10’ X 21’

- 15,000 LP Storage Tank- Horizontal

- #2 Fuel Kohler Generator

3 Ton Cedar Rapids Asphalt Batch Plant [SOLD]

Current Location: Middleton, WI

- 4 Ton Batch Hopper

- (4) Virgin Aggregate Bins 15’ X 9’

- (2) RAP Bins 8’ X 6’

- RAP System Conveyor

- 28’ Length X 7’ Diameter Chain Drive Drum- Cedar Rapids

- 61.6 MM BTU/HR Genco Burner

- SQI 33 Baghouse- Barber Green

- Genco Hy-Way Hot Oil Heater-SFGO-70

- (2) 15,000-gallon Horizontal AC Tanks

- 400 Ton/Hr Bituma Drag Slat

- 400Ton/Hr Bituma Transfer Conveyor

- (2) 200 Ton Bituma Storage Silos

- 100K Rice Lake Survivor Truck Scale

- 375 KVA Diesel Generator

- Control House w/Gencor Controls

- Petroflex Fiber Feed

- Crum Rubber Hopper & Heated Auger

- 25hp Quincy Air Compressor

- (2) Fuel Tanks

- 200 Ton/hr Bucket Elevator

- Gencor Hy-Way Hot Oil- Pre-Heater