At Motion Engineering, we specialize in supplying and sourcing Honeywell, Hauck, Eclipse & Maxon parts for asphalt plants. For over 120 years, the Elster Hauck brand has been synonymous with reliable and durable asphalt plant burner equipment.

These components, trusted for combustion applications involving asphalt, aggregate, sand, and more, are critical to running your operations smoothly. Our wide range of in stock Honeywell parts and Hauck burner parts ensures your plant’s efficiency and minimizes downtime.

Critical Honeywell Parts for Asphalt Plants

Hauck parts have earned a reputation for their rugged durability, capturing a significant share of the asphalt plant market. Many plants still operate with Hauck burners, which are built to last up to 30 years. However, maintaining these burners requires regular replacement of parts. Because of the age and demand for these parts, sourcing can often lead to long delays. That’s where Motion Engineering steps in. We offer in stock Honeywell parts, including Hauck Starjet replacement parts and Hauck TBA blowers, ensuring timely access to crucial components without the hassle of long lead times.

Our Hauck burner parts are compatible with various fuel types, including:

- Natural Gas

- Light Fuel Oil #2

- Heavy Oil #4, #5, and #6

- Waste or Reclaimed Oil

- Liquid & Vapor Propane

- Liquid & Vapor Butane

This versatility allows for greater flexibility in your operations while relying on the dependable Honeywell Hauck systems.

Why In Stock Honeywell Parts Are Key to Reducing Downtime

The reality of today’s market is that lead times for Honeywell parts can be extensive, often delaying critical repairs and replacements. Many asphalt plants rely on Honeywell burner parts to maintain operational efficiency. Waiting for extended lead times can severely impact production schedules and lead to unplanned downtime.

At Motion Engineering, we combat these challenges by offering an extensive inventory of in stock Honeywell parts that are immediately available. From Hauck blowers and Hauck burner replacement parts, we ensure your facility has what it needs to stay productive.

Extensive Honeywell Hauck Product Range

Our Honeywell Hauck product range includes a variety of critical components, such as:

- Burner parts for the Hauck asphalt burners

- Control valves and actuators designed for durability and reliability

- Replacement parts for the Hauck Starjet, Megastar, and Ecostar systems, ensuring optimal performance

- Blower fan parts to enhance airflow and burner efficiency

With these parts readily available, we minimize the disruption caused by equipment failures. Our focus on stocking the most essential asphalt plant parts means less downtime for your business.

Get Honeywell Parts Today

If you’re looking for Honeywell parts or Hauck burner parts, Motion Engineering is here to provide the solutions you need. Our extensive stock of in stock Honeywell parts ensures you won’t have to deal with long lead times or production delays. From Hauck blowers to Ignition Gas Pilots to other essential asphalt plant equipment, we are your go-to source for maintaining your plant’s efficiency.

Contact us today to get access to in stock parts that are immediately available!

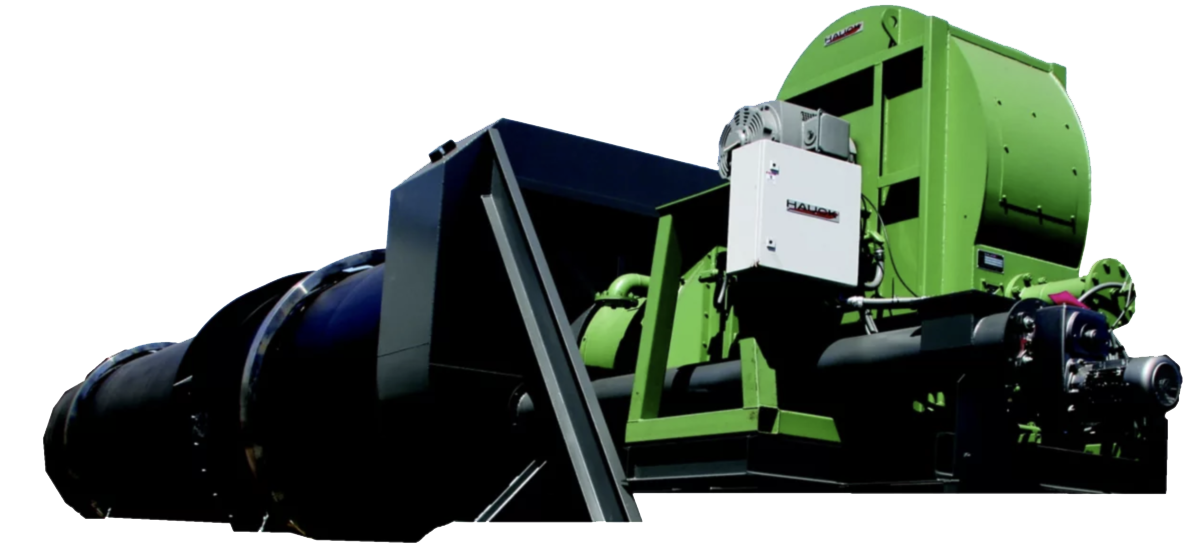

MegaStar

Packaged, High Efficiency, Multi-Fuel Burner for Aggregate Drying Applications. The MegaStar is designed to be easy to light, reliable, and efficient.

The MegaStar burner supports a wide variety of liquid and gaseous fuels offering flexibility for optimizing fuel costs. Low pressure atomization is used for light fuel oil or LP with high pressure compressed air atomization available for heavy fuel oils or high elevation installations. Emissions of NOX, CO and VOCs are minimized with proven and effective technologies.The burner’s wide range of flame shaping ability allows the flame to be adapted to specific process requirements. All combustion is completed within the recommended combustion zone, keeping emissions low by eliminating flame quenching from process materials. The MegaStar employs variable frequency drive (VFD) technology for precise air flow control over its entire operating range. Combining precise air flow control with real time fuel flow measurement results in maximum combustion efficiency and cost savings. The use of this VFD technology offers energy savings through reduced electricity consumption. The burner package is compact and easy to install, yet remains accessible and simple to service. The number of moving parts has been reduced and linkages have been eliminated to make the burner easy to maintain and adjust. The burner, paired with a Hauck BCS7000 panel, provides the ultimate solution for flame management, process control, and efficiency.Available in sizes ranging from a nominal 25 to 150 million Btu/h (7,327 to 43, 960 kW), for applications up to 1500 oF (815 oC). Custom lengths are also available for warm-mix applications.

Features & Benefits:

- Energy savings

- Low NOX emissions

- Low motor starting current reduces utility demand charges

- Ideal for sand drying applications

- Reduction of thermal and mechanical stresses on the motor during starts

- Standard and longnose versions available

- Simple installation and set-up

- High power factor

- Lower KVA

VIEW PART NUMBERS >

NovaStar

Ultra low NOx emissions burner designed for aggregate drying applications.

Utilizing the latest patented lean burn premix technologies, the NovaStar offers design and performance advantages with service accessibility and ease of installation. Available in various sizes the NovaStar is ready to meet your production needs and even the most stringent air quality standards with ultra low nitrogen oxide (NOx) emissions on gaseous fuels without the added expense of flue gas recirculation (FGR) technology. The burner can be easily operated and effectively managed with PLC based control provided by Hauck’s BCS products. The burner produces a compact flame making it suitable for all drum sizes and types. This further reduces emissions by completing all combustion within the short combustion zone eliminating flame

quenching from process materials.

Features & Benefits:

- Ultra low NOx emissions of that meet most stringent air quality standards without FGR or water injection on natural gas and vaporized propane

- Standard and long-nose variations available to suit all drum types

- Advanced construction for ease of installation and maintenance

- Precise air flow control via VFD and low horsepower design offers significant energy

savings - Compact modular design suitable for stationary or portable plants

- Sealed-in design for ultra quiet operation and maximum fuel efficiency

VIEW PART NUMBERS >

StarJet

Open-Fired Multi-Fuel Burner for the aggregate drying industry.

The StarJet burner is designed to recirculate the hot gases, providing flame stability over its wide operating range. This eliminates the need for refractory ignition tile and combustion chamber. The StarJet can have the short, bushy flame for drum mixing or a

long flame depending on the application. The burner’s wide turndown is particularly

useful when lower production rates are desired, such as when making cold patch material.

Features & Benefits:

- No ignition tile

- No combustion chamber required

- Convenient flame shaping

- Wide turndown

- Compressed air option available

- Fuels fired:

- Heavy Fuel Oil

- Light Fuel Oil

- Natural Gas

- Liquid Propane (LP)

- Landfill Gas

VIEW PART NUMBERS >