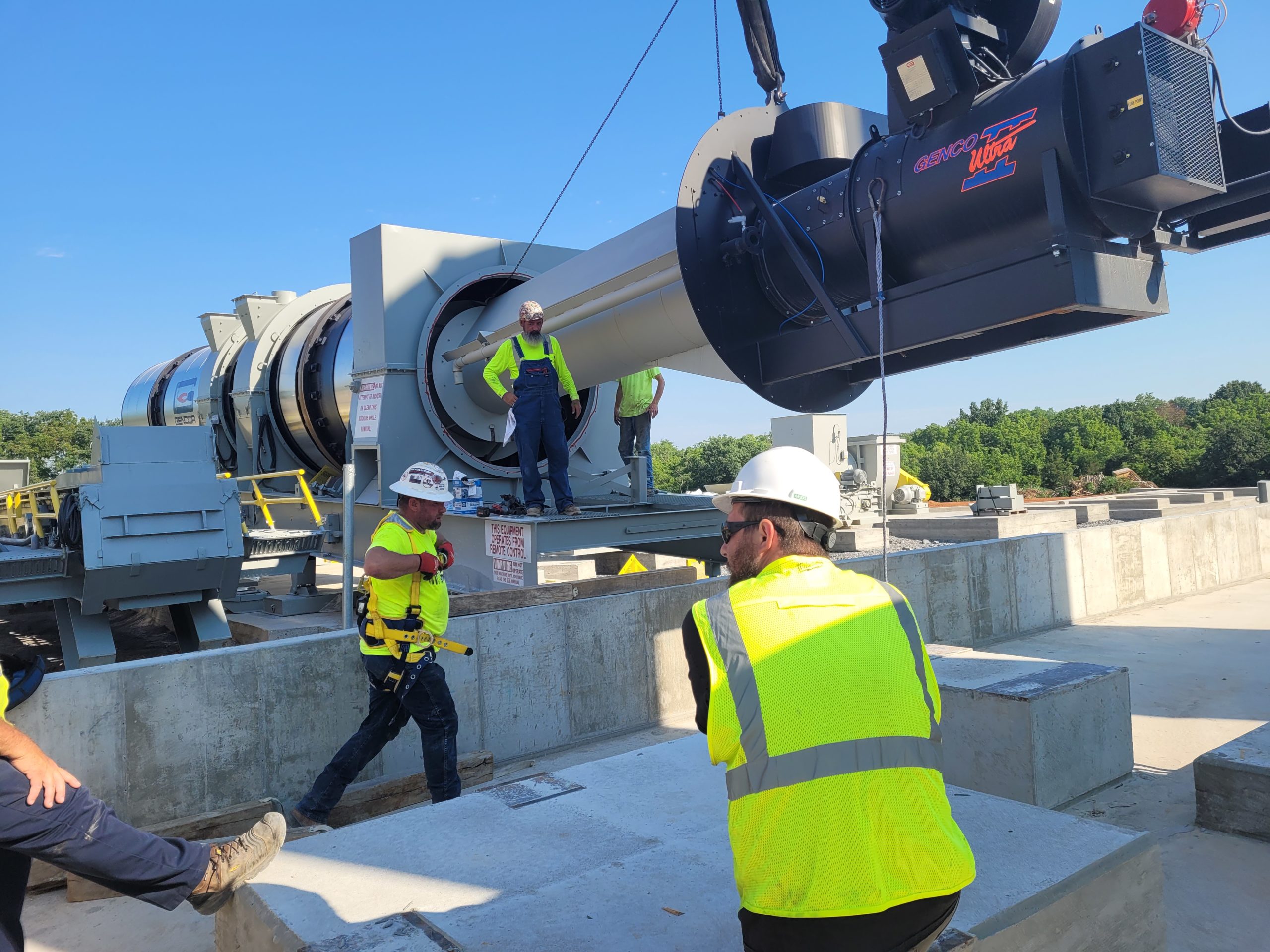

With the cost of steel skyrocketing, a new asphalt plant can be a massive expense that might far exceed your budget. However, options like dismantling an existing plant, relocating it to a new location, and setting it up can be a more cost-effective alternative. Motion Engineering has the experience and knowledge to safely and effectively handle your asphalt plant relocation. We create a solution that gets your plant properly set up and within your budget. Our turnkey solutions include teardown and relocation of your asphalt plant.

As a business, we intentionally run lean so that we are able to pass the savings on to you. We do so by renting the equipment we need for the particular job, rather than maintaining a fleet of cranes and other equipment that would sit unused. This approach also allows us to ensure we have what we need, whether it is manlifts, off-road forklifts, or skid steers.

What if you are looking for labor and assistance, rather than a full asphalt plant relocation? We can do that too! You do not have to worry about bundled services that don’t actually serve your needs. Motion Engineering is here to save you money on whatever services you need to make your asphalt plant relocation as smooth as possible.

Why Relocate An Existing Asphalt Plant

There are several reasons to consider relocation rather than building a new asphalt plant. One such reason includes if you are new to the industry. Many who are new to the asphalt industry have entered the market in order to save money by making their own rather than buying from local producers.

However, if you are already established in the industry, you may want to relocate an existing plant for other reasons. Some of these reasons include moving to a more convenient location or to a more resource-rich area for aggregate. Another reason to move an existing plant is if you are experiencing high growth and are looking to upgrade.

Update Your Plant Equipment

Is it time to move beyond your antiquated controls and burners? If so, we can update or swap out your asphalt plant equipment. Not sure if your equipment is due for replacement? Be sure to prioritize control systems and other electrical systems, which should be updated in an outdated plant that features older equipment. Replacing electrical and control systems will ensure safety and ongoing functionality.

Additionally, replacing older, clunky pieces of equipment can help to clear up space as newer models tend to be more streamlined and compact. In terms of prioritizing non-electrical items to upgrade, focus on your burners, which should be kept up to date if it is affordable for you to do so.

When you’re upgrading, it is also a great time to switch to vertical tanks. This economical upgrade will save you money on heat costs as the vertical tanks are more energy efficient. And as a bonus, they require less real estate than horizontal tanks.

Partner with Motion Engineering for your Asphalt Plant Relocation

Motion Engineering is your trusted partner for asphalt plant relocation and equipment updates. With the soaring cost of steel, building a new plant may exceed your budget, but our cost-effective solutions, including dismantling and relocating your existing plant, provide a viable alternative. We run a lean operation, renting equipment specific to each job to pass the cost savings on to you, while ensuring we have the necessary machinery.

Whether you are new to the asphalt/bitumen industry or an established player, relocating an existing plant offers benefits such as cost savings, convenience, resource-rich locations, and upgrades. We also offer equipment updates, prioritizing control systems and electrical components for safety, functionality, and efficiency. Consider switching to vertical tanks during your upgrade for economic and energy-efficient advantages. Contact Motion Engineering today to discuss your needs and achieve a smooth asphalt plant relocation or equipment upgrade within your budget.