Motion Engineering is your go-to solution when it comes to hot oil piping, AC piping, and trace-line heating services for asphalt plants. We specialize in these procedures, harnessing their efficiency to optimize the heating of asphalt cement (AC) pipes. As seasoned players in buying and selling industrial asphalt plants and associated equipment, our mastery over these services is unrivaled.

Mastering the Art of AC Piping

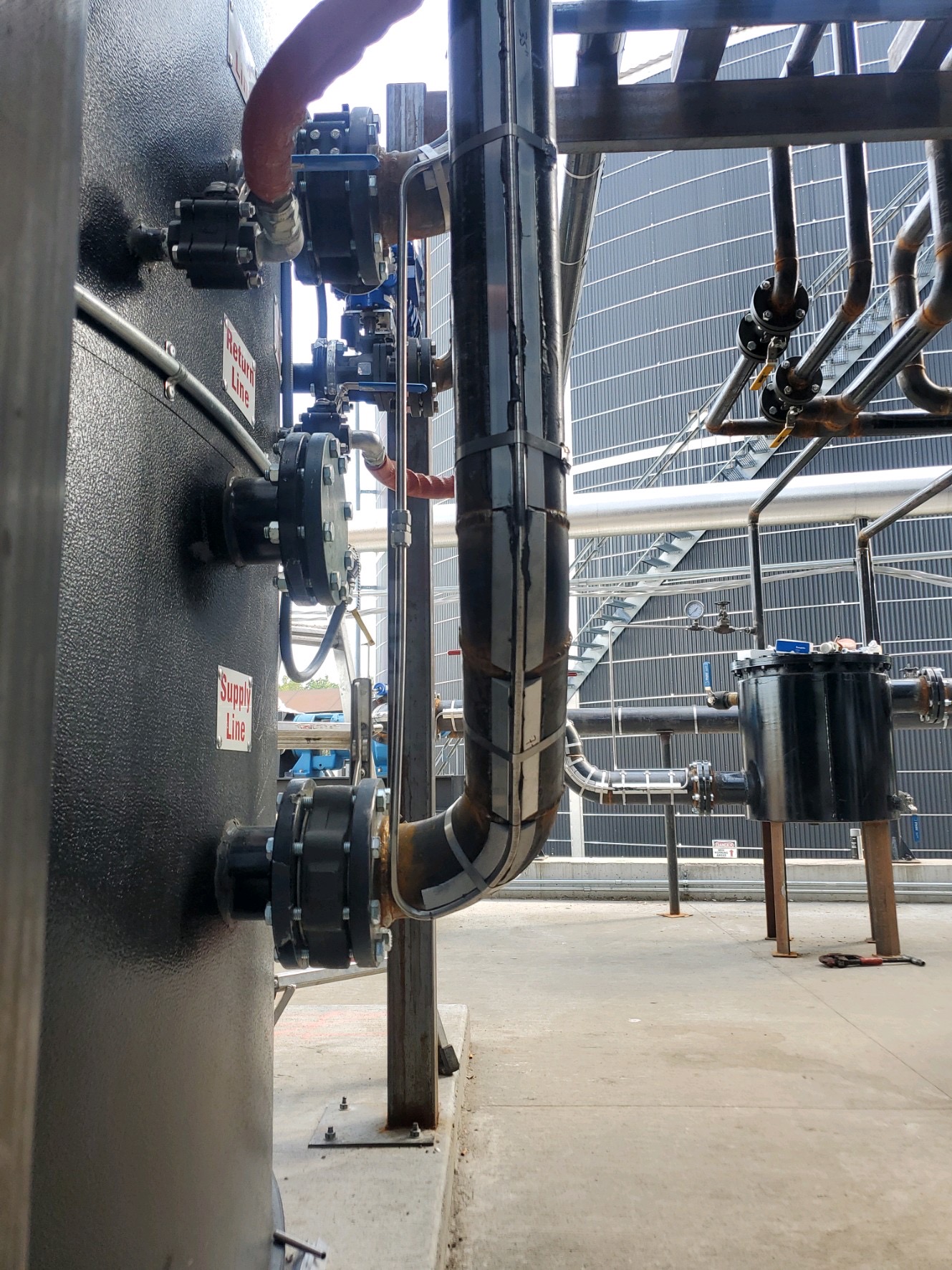

At the core of an asphalt plant, AC piping systems are constructed for the purpose of transferring AC from storage tanks to the plant for metering processes. These systems are needed for offloading trucks, pumping from storage tanks to other tanks, or directing to and within the asphalt plant for production. As such, our services consider various factors in the design and installation of AC piping systems, including the specific needs of your plant and the desired temperature. Moreover, potential leaks in the AC piping can be readily identified, ensuring the smooth running of your asphalt plant.

What is Hot Oil Piping?

Hot oil piping systems are a method of heating pipelines, tanks, pumps, and other industrial instruments, particularly for asphalt plants. In comparison to steam methods, hot oil piping offers a wider temperature range along with lower operating pressure. They heat the product within a pipe similarly to a boiler but with hot oil.

There are two forms of hot oil piping. The first one involves placing a pipe over the interior piping with hot oil running through the outside, jacketed pipe. The second form involves attaching a separate pipe that operates through heat transfer. The latter is generally the more economical approach as it involves fewer materials.

What is Trace-Line Heating?

Combining trace-line heating with insulation provides an economical and dependable means of maintaining the temperature of AC liquid at a minimum of 300 degrees. Leaks in the AC piping and hot oil piping are easy to detect, making for swift and cost-effective repairs. Trace-line heating involves two separate tubes or zones attached together rather than welded. This trace line is then attached to the AC piping, ensuring optimal flow throughout the system. With trace-line heating, you won’t have to worry about a “slug” forming in cold spots of improperly insulated piping. The result is an efficient, reliable system that saves on maintenance and replacement costs.

Protect Your Investment with Hot Oil Piping and AC Piping

All pipelines carrying asphalt cement require some sort of heat to move the liquid; without this heat, the liquid will not flow. Heating ensures optimal flow throughout the system. Conversely, improperly insulated piping can lead to the formation of “slugs” in cold spots, an occurrence that may be detrimental to your plant’s functionality and profitability.

Insulation is key in reducing energy consumption and costs, thus causing less strain on the hot oil burner system due to fewer cycles. Coupled with our insulation services, you can rest assured that your oil piping and AC piping are working at their maximum potential.

Contact Motion Engineering today to learn more about our services.